Educational

Resources

Unlocking Potential: How STEM Learning Experiences Shape Young Minds

STEM learning experiences, encompassing science, technology, engineering, and mathematics, are crucial for primary school students as they lay the foundation for critical thinking, problem-solving, and innovation. Engaging with STEM subjects at an early age helps children develop a curiosity about the world around them and an understanding of how things work. These experiences can foster a lifelong love of learning and exploration, encouraging students to ask questions, seek answers, and develop solutions to real-world problems.

STEM education is vital for preparing students for the future job market. As technology continues to advance rapidly, many future careers will require STEM skills. By cultivating these skills early, primary school students will be better equipped to navigate a technology-driven world and seize opportunities in emerging fields. STEM learning experiences often incorporate teamwork and collaboration, teaching students how to work effectively with others, communicate their ideas, and integrate different perspectives to solve problems. These soft skills are just as important as technical knowledge in today’s job market.

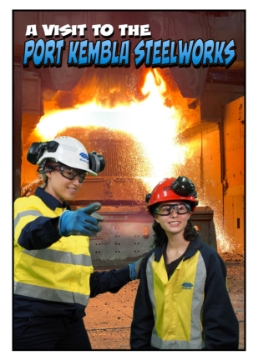

Through our guided tours, we aim to introduce students to industry through real life experiences.